Discover All Products

Since 1997, ARM TELCİBEY® Makine Ltd. Şti. has been operating in the metal processing industry, continuing its production journey with the same passion and determination it had on day one. With deep-rooted experience in the sector, our company has embraced the principles of quality, trust, and innovation, and continues to grow by prioritizing customer satisfaction.

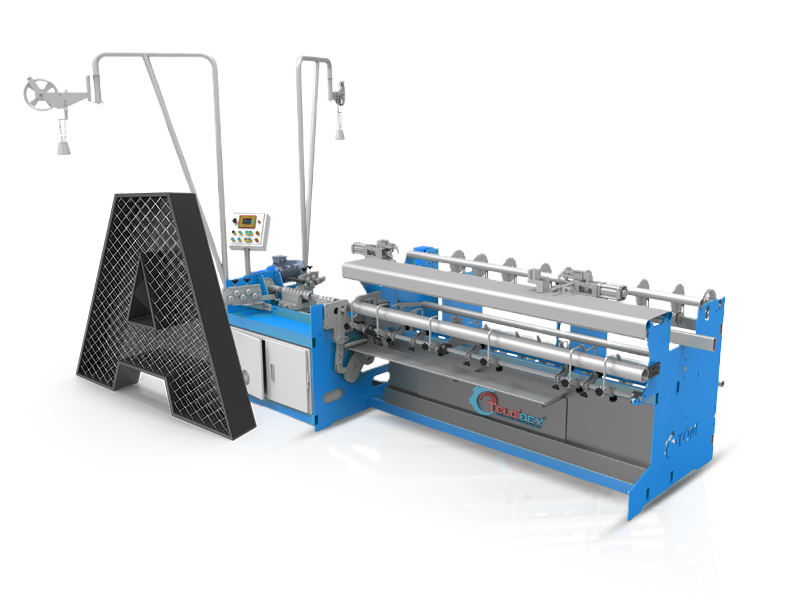

Closely following evolving production technologies, ARM TELCİBEY® today leads the industry with specialized product groups such as Grass Fence Machines, Panel Fence Spot Welding Machines, Spiral Wire Weaving Machines, Barbed Wire Machines, Razor Wire Machines, and Steel Mesh Spot Welding Machines.

Years Experience

Production Area

Export to Country

News