Barbed wire machines are designed to apply pre-shaped barbs at fixed intervals such as 8, 10, or 12 cm onto two main carrier wires that have been twisted together. This process results in the production of barbed wire.

Many existing barbed wire machines perform this process using four wire inputs and wind the finished barbed wire onto a spool located within the machine. Once the desired length is reached, the machine stops, the operator removes the full spool, installs an empty one, and restarts production. This spool changing process causes significant time loss. Furthermore, the repeated bending and lifting required during spool replacement can become tiring for the operator over time.

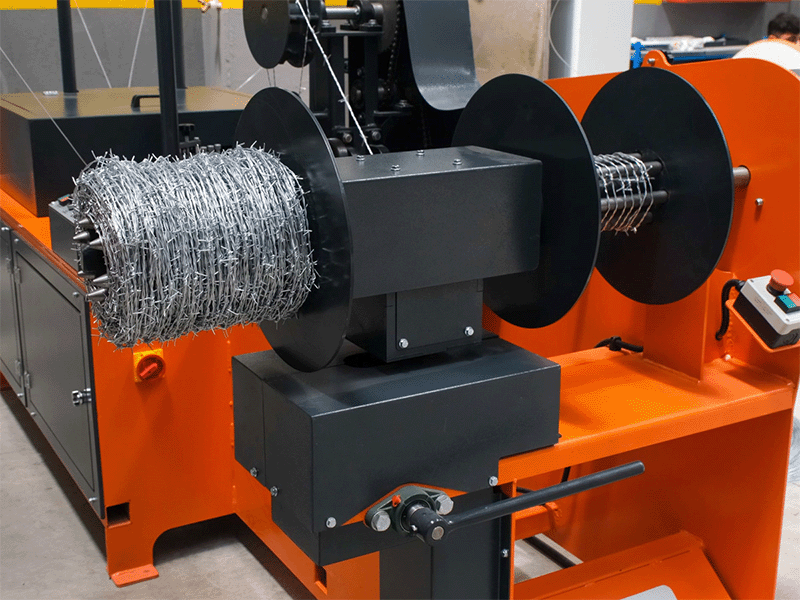

With the DKN Pro model barbed wire machine produced by ARM Telcibey®, both of these undesired issues are eliminated. The DKN Pro does not use spools. It features a dual-direction winding system. Once the first winding side is complete, the operator simply changes the winding direction with a single lever, allowing continuous production. The completed roll on the other side can then be detached and used as a finished barbed wire coil. This way, the operator avoids unnecessary fatigue, and the machine continues production without any interruptions.

With the DKN Pro Barbed Wire Machine, you can produce up to 1,000 meters of barbed wire per hour.

For more information: https://www.armtelcibey.com.tr/fully-automatic-barbed-wire-machine

For direct contact, you can reach us via our WhatsApp line: +90 505 379 95 99